Cold Chain Management

Temperature-sensitive goods

supervision and compliance

supervision and compliance

Cold chain compliance in the automotive transport sector is a

major issue, both for public health and for economic reasons.

major issue, both for public health and for economic reasons.

Temperature monitoring is essential to keep a detailed control to

avoid fines, avoid food wasting or other heat-sensitive goods in

the cold chain management, facilitating detailed information of

the entire trip, reducing risks and considerably increasing the

return on investment.

avoid fines, avoid food wasting or other heat-sensitive goods in

the cold chain management, facilitating detailed information of

the entire trip, reducing risks and considerably increasing the

return on investment.

The heat-sensitive goods transport is subject to numerous standards and regulations.

The cold chain breach can have serious repercussions and

needs to be controlled precisely and regular basis.

The cold chain breach can have serious repercussions and

needs to be controlled precisely and regular basis.

To meet this challenge and allow carriers to secure the goods for which they are responsible, Didcom has developed a real time remote temperature monitoring solution with Bluetooth Low Energy sensors.

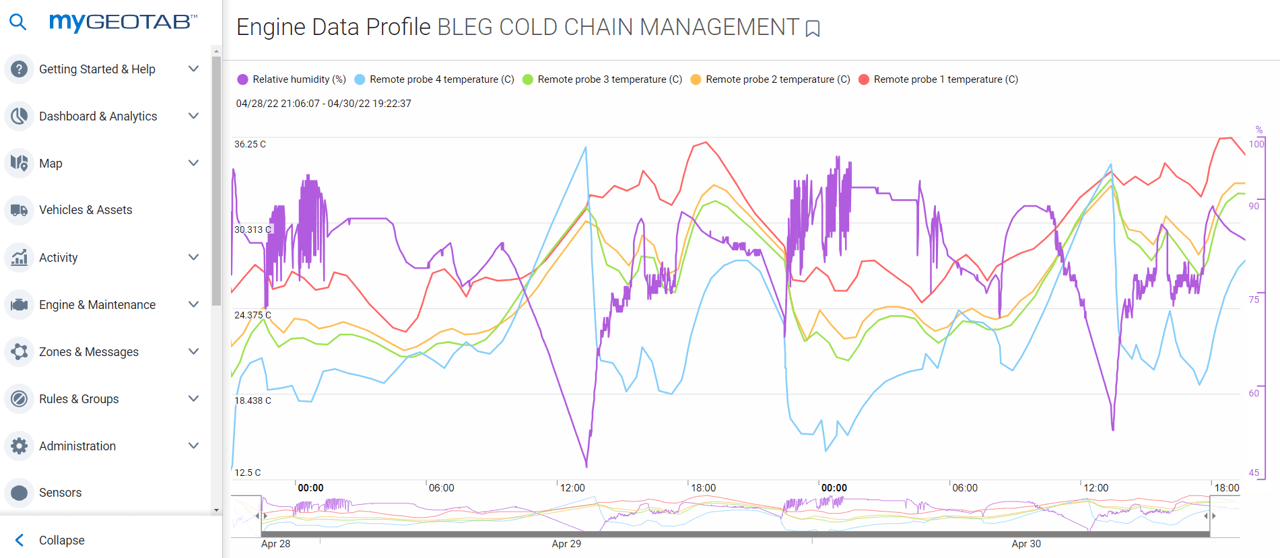

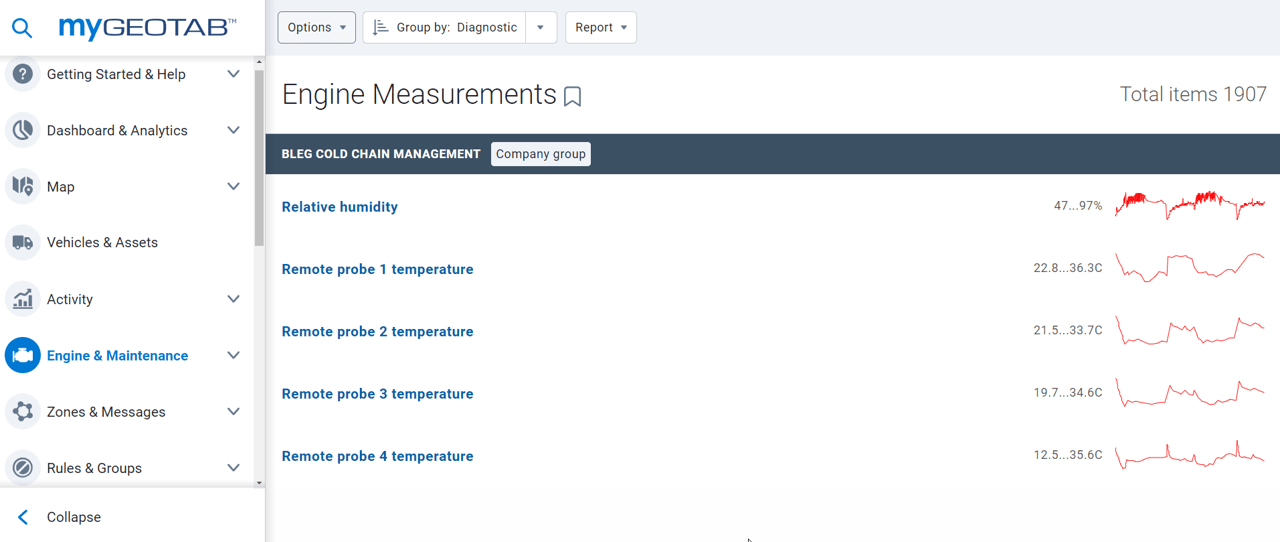

Temperature sensors can be fixed in different areas of the

refrigerator trailer to know the temperature behavior in

different zones, establishing monitoring automation and

notifications linked to every temperature record with

real-time positioning information for the precise decision

making.

The temperature log records are obtained through Didcom BLEG and transmitted in real time via the GO device, which will send all the information to MyGeotab.

refrigerator trailer to know the temperature behavior in

different zones, establishing monitoring automation and

notifications linked to every temperature record with

real-time positioning information for the precise decision

making.

The temperature log records are obtained through Didcom BLEG and transmitted in real time via the GO device, which will send all the information to MyGeotab.

Features

Supervise and secure the transportation of temperature-sensitive goods with wireless bluetooth temperature sensors in order to provide precise and trustful cold chain traceability to ensure regulatory compliance.

This solution provides detailed information about the entire trip, reducing compliance risks and helping to ensure return on.

This solution provides detailed information about the entire trip, reducing compliance risks and helping to ensure return on.

Transported

cargo control

cargo control

Reduction in fines and less merchandise rejection

Detail temperature log for cold chain audit

Elimination of costs due to deterioration

claims

claims

We help you optimize your vehicle fleets!

Tell us what you need and we will provide the most appropriate solution.