Analysis and Engine Health

Know the operation and convert corrective into preventive maintenance

Engine Data Analysis

Know the operation and convert corrective into preventive maintenance

Didcom EPC is a monitoring and reading solution for multi-brand automotive protocol that converts proprietary CAN protocols of various speeds to the J1939 standard protocol, obtaining parameters and fault codes, also functioning as a bypass filter that allows the reading of various parameters under programming.

Integrated IOX-Didcom technology for direct connection to telematics equipment (Geotab® GO9) without the need for additional accessories.

The information obtained through the EPC solution is sent, via the telematics device, to the cellular network and received by the platform to generate a wide variety of reports that streamline their visualization and analysis, supporting intelligent decision-making.

Features

Parameter Implementation

How does it work?

Didcom EPC allows you to add and edit filter parameters through the ADD communication port, which is interconnected to the telematics device via two-way communication.

The correct use of the information received through the EPC solution allows you to schedule maintenance based on the odometer record, reduce fuel consumption due to mechanical damage, mitigate incidents due to road trips, extend engine life, and evaluate driving metrics.

The Didcom development team can support the creation of automated reports for efficient interpretation of the collected data.

Safety parameters

Increase the safety of your drivers and cargo

Vehicle performance parameters

Monitor your vehicle's usage and reduce maintenance costs

Trip parameters

Analyze driver-aware driving behavior and reduce fuel costs

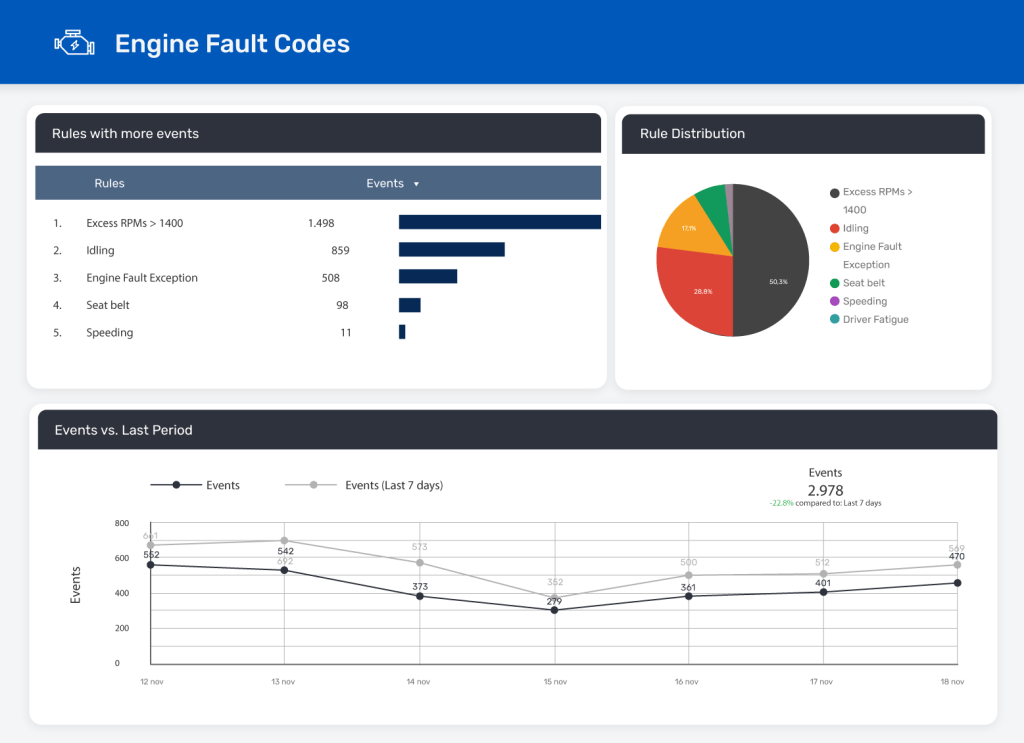

Wide Operational Visibility Through Engine Data

The information received is divided into two essential parts: Engine Data and Fault Codes. Each processed data item can be referenced with a value and date, creating historical tables of each record to streamline analysis and identify behavioral trends.

Wide Compatibility with Manufacturers and Technologies

Didcom EPC can be used on compatible multi-brand buses to read and interpret engine data and fault codes, whether standard data or proprietary manufacturing data.

The EPC solution provides broad and robust compatibility with vehicles from multi-brand manufacturers and diverse mobility technologies at the forefront of the transportation industry, streamlining their standardization and integration into fleet operations.

Driving the Standardization and Integration of New Technologies

The solution and its integration

Didcom Engine Protocol Converter - V4.0 ®

Didcom EPC offers a plug-and-play design with IOX Protocol integration. The device can be integrated into telemetry equipment that supports SAE J1939 CANBus connection via the OBDII connector on terminals 6 (CANHigh) and 14 (CANLow).

The EPC device integrates four visible LED indicators for the user to view data transmission and perform any troubleshooting.

Engine Data Analysis

Understand the operation and convert reactive and corrective maintenance into preventive and predictive maintenance to ensure its optimal condition and performance

REACTIVE

CORRECTIVE

PREVENTIVE

PREDICTIVE

Success Stories

Driving global change through technology development and integration

Our success in technology development and integration is driven by providing specialized telematics solutions, reflecting our focus on specialized engineering and high-value creation. We are committed to innovation and strategic excellence, developing solutions that improve fleet productivity, efficiency, safety, and satisfaction.

Ensure Safe and Optimal Vehicle

Condition on the Road!

Didcom EPC is an innovative telematics solution that streamlines monitoring of the engine status and performance of fleet vehicles through technology and data digitization.

Our solution helps fleet management manage maintenance in a standardized manner to ensure the best condition and performance of vehicles on the road, strengthening safety and operational efficiency for the benefit of its customers.

Multi-brand engine data

visibility and analysis

visibility and analysis

Engine fault code

reading and translation

reading and translation

Proactive maintenance scheduling

Protection of engine

integrity and performance

integrity and performance

Savings against excessive costs due to mechanical failures and related malfunctions

Extension of engine, battery

and electrical system lifespan

and electrical system lifespan

Reduced downtime due

to inspection and repairs

to inspection and repairs

Prevention of incidents

due to trip failures

due to trip failures

Reduction in fuel consumption due to mechanical breakdowns or failures

Increased safety through

evaluation of driving metrics

evaluation of driving metrics

Standardization of information and integration with third-party systems owned by the client

Digital transformation of tasks and processes and streamlining of timelines

We help you optimize your vehicle fleets

Tell us what you need and we will provide you with the most appropriate solution.